Production

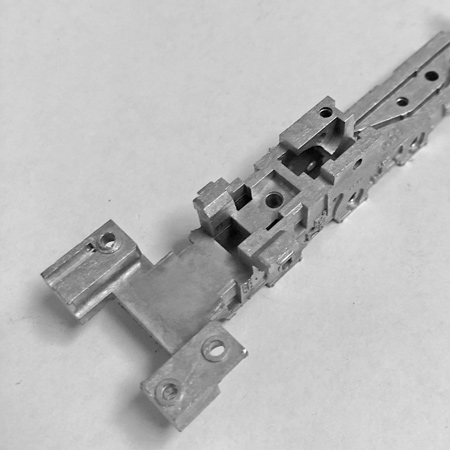

Aluminium parts

Gravity casting and Low/High pressure Die casting process. Lightweight and able to withstand the highest operating temperatures of all die cast alloys. Strength, hardness, stiffness, high electrical conductivity, corrosion resistance and full recyclability. Production of aluminum sheets and profiles of various sizes. Manual & Mechanical treatment: tumbling, grinding, polishing, degreasing, drilling, threading and surface coating of various types - color and powder coating. Material used is Aluminum Alloy A380 which is one of the most commonly used aluminum alloys.

Zamak parts

High pressure Die casting process. High quality finishing characteristics, and outstanding corrosion resistance. Manual & Mechanical treatment: tumbling, grinding, polishing, degreasing, drilling, threading and surface coating of various types - color and powder coating and galvanic coating.

Steel parts

Cold forming of steel, steel and stainless-steel sheets, profile steel and pipes - cutting/separation, milling, drilling, turning, threading, degreasing, pressing, welding and surface coating - color and powder coating.

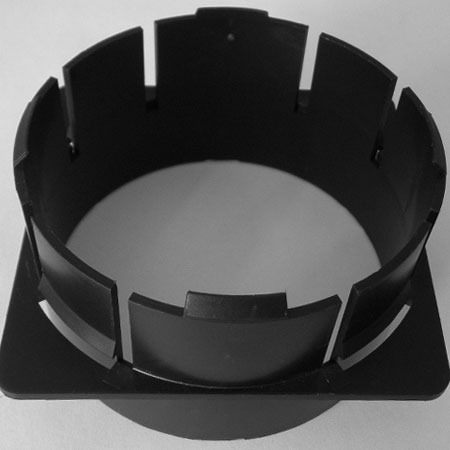

Plastic parts

Plastic injection molding - the process of manufacturing by shaping liquid or pliable material using a rigid frame called a mold or matrix. Injection molding is our most commonly used process. Material used in production: ABS and others.

Wooden parts

Solid wood products (tables, bathroom counters, desks, vanities, stools and many others) made out of spruce, oak, pine and other typical material for this specific region. Exotic timber plays also an important role in our portfolio.

Surface Finishing

We offer various types of surface coating. Manual color and powder coating process using NCS or RAL colors. Galvanic decorative coating process - Cu, Ni (shiny & mat), Cr (shiny & mat), Brass, and Patine.

Packing & Assembly

Corrugated boxes (3-5 layers) are used for packing most of the products from the production. Frequently used as a bulk shipper, delivering many similar products in the same box, if needed. Drilling, thread cutting and assembly of semi-finished or finished products including a detailed specification.